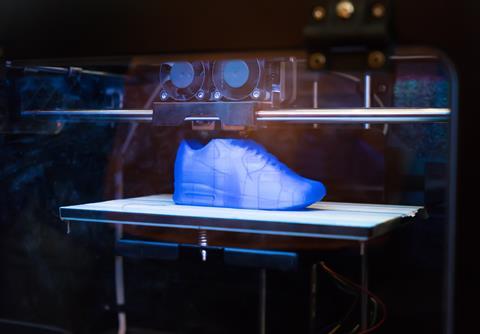

Germany is developing a distinct competitive edge in this emerging technology. But the realisation phase of this new tech’s life cycle has brought with it many questions concerning product liability and more.

From spare parts for the automotive sector to aircraft components and consumer goods, 3D printing technology can be produced quickly and inexpensively, with the added benefit that items can be more easily personalised.

German chemical giant BASF is among those taking significant strides in additive manufacturing and is collaborating with a growing network of organisations in an effort to take the applications of 3D printing beyond the prototype phase.

The field of 3D printing for industrial applications is highly dynamic and still emerging. his means there is a need for agile, start-up-like structures with interdisciplinary teams and quick decision-making processes.” - Volker Hammes, managing director at BASF

“The field of 3D printing for industrial applications is highly dynamic and still emerging,” said Volker Hammes, managing director at BASF New Business, and future managing director of BASF 3D Printing Solutions. “This means there is a need for agile, start-up-like structures with interdisciplinary teams and quick decision-making processes.”

3D printing offers a blueprint for other digitalisation activities in smart factories, according to Michael Bruch, head of emerging trends at Allianz Global Corporate & Specialty, and raises important questions surrounding product liability.

“There are challenges when you are actually automating a process that has previously been operated by human beings. There are a lot more new players involved in this new manufacturing process.”

“With 3D printing, you have the product designer, who does the coding of what has to be printed, and then you might have an internet sales platform,” Bruch continues. “You have the manufacturer of the 3D printer, and you have the operators. So, as you can imagine, if something goes wrong it’s very hard to trace back who was actually liable for this unsafe product.

“The other big question is over whether software or coding can be defined as a product. I know that in Switzerland, for example, they classify even the software for a 3D printer for medical devices as a product.

And that means someone who is writing the software or doing the coding is responsible for recall if it turns out to be unsafe. But that’s an extremely challenging and difficult process to exercise.”

Every new tech has to go through a life cycle, according to Bruch. “In the beginning, everybody thinks this is the future and gets very excited. And then you go through the realisation phase, which is where we’re at now with 3D printing.”

No comments yet