Ed Mitchell and Thomas Zanner explain how to deal with recalls in the food and drink industry

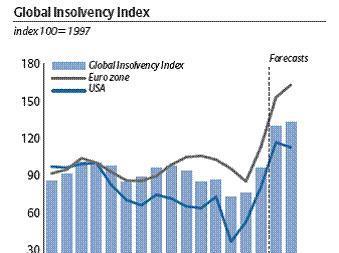

Food and drink companies around the world are operating in an unprecedented product recall risk environment. Not only are companies feeling the pinch from the global economic climate but they are also having to contend with the challenges of a significant shift in the regulatory environment surrounding food safety and product recalls.

Companies are forced to cut costs but they must ensure that this does not compromise food safety as regulators and the media put the food and drink industry under ever greater scrutiny. Additionally, events over the last few years have exposed the potential weaknesses of the global supply chain.

A decade ago outsourcing to the far corners of the world made good economic sense, but today companies need to factor in the risks that this can present and the potential brand damage it may cause.

Last year was marked by a number of major product recalls around the world. This was most tragically illustrated by the death of four babies and multiple other injuries caused to children in China by melamine-contaminated milk. The tragedy led to a massive recall of products not only in China but around the world. And, in December 2008, the Food Safety Authority of Ireland recalled all Irish pork due to its contamination by dioxins. In early 2009 salmonella contaminated peanuts in the US led to a nationwide recall.

Regulatory risk

The cost of product recalls to the food and drink industry can be very severe in financial terms. But it is the government focus on the cost to society caused by recalls and food borne illnesses that has led to a push for change in laws and greater regulatory enforcement powers. The result for risk managers and company directors is a significant increase in risk. As such it is becoming critical for companies to be aware of their regulatory obligations and to ensure that they are putting only safe products into the market. Getting it wrong is no longer just a financial risk, in some cases it can lead to criminal prosecutions.

In Europe it is four years since the implementation of Regulation (EC) 178/2002. This regulation set out for the first time specific obligations on food and drink companies with regard to product recalls. It places an obligation on companies to recall a product that is either ‘injurious to health’ or ‘unfit for human consumption’. While the regulation is ultimately aimed at protecting the consumer it can create additional risk for food and drink companies when it comes to making a product recall decision based on this criteria, particularly when the company has an obligation to involve the local regulatory authority.

The Food Safety Authority of Ireland (FSAI), for example, required the recall of Irish pork in December 2008 because the pork contained dioxin levels that were considerably higher than legally permissible. Interestingly, the FSAI consumer website was clear in stating that: ‘Even though it is illegal for dioxins to be present in foodstuffs above legal limits, any possible risk to consumer health is extremely low. Even in the unlikely event that you have eaten a large amount of the most highly contaminated products every day since September 1, you should not experience any adverse health effects … There is no risk of immediate illness. If you have eaten an affected product, the risk to long term health is minimal, however not eating it any more is a sensible thing to do. It is continued high level exposure to dioxins over time that gives cause for concern.’

From a regulatory standpoint the future looks bleak for food and drink companies, particularly if decisions about food safety and product recalls start to shift from industry to government. As regulators push for greater enforcement powers, risk managers need to be aware of the increased risk as the decision to recall could change from being voluntary to mandatory. And the ultimate decision could be taken away from the company.

Referring to the creation of a new food safety working group in his weekly address on 14 March 2009, US president Barack Obama said: ‘There are certain things only a government can do. And one of those things is ensuring that the foods we eat … are safe and don’t cause us harm. That is the mission of the Food and Drug Administration and it is a mission shared by our Department of Agriculture.’

Europe and the US have had their fair share of product contamination and food borne illness problems over the last few years and therefore it is understandable that governments seek to impose stricter laws and greater control. Companies need to be aware that they will be operating in a far more onerous environment and ensure they are best positioned to manage the exposure.

Supply chain risk

Companies in Europe have an obligation to ensure they have an appropriate traceability plan in place. The traceability plan must adhere to the ‘one step up, one step down’ principle so that the company can immediately know not only where the product (or its ingredients) came from, but also the next person to whom it has gone.

Being able to trace a product, however, is only part of the solution. While this allows products to be traced along the food chain it does not eliminate actual contamination. As the recent peanut recall in the US has demonstrated, the effect of a contaminated product entering the food chain can be wide reaching. For any manufacturer a reliable supply chain is critical, yet the risk is that every time a company reaches out to a supplier it is putting its brand in someone else’s hands.

In the current economic climate this is a particularly challenging issue. Historically food and drink manufacturers have relied on certificates of analysis to ensure that the ingredients and raw materials they receive are safe. Testing incoming products and auditing suppliers is an expensive business.

“It is critical for companies to be aware of their regulatory obligations

Despite the pressures on companies to cut costs, the question is to what extent companies can afford to take the risk of not knowing what is coming into their manufacturing plants?

Reputation risk

Not only are food and drink companies working to contend with the challenges of the economic downturn, regulatory change and the supply chain; they are also faced with significant risks to their brand and reputation. Consumers expect to get instant answers and analysis to very complex situations, while any delay in providing information could harm the brand. The food and drink sector has experienced a number of well publicised challenges in recent years and some companies have been caught on the back foot at a time when they need to act fast to protect their brand.

As companies become more exposed to the potential of having product recalls, it is vitally important that they are in a position to manage any media crisis that can accompany one.

Protection

Regulatory, supply chain and reputation risks are not the only issues facing food and drink companies today. Bio-terrorism, straightforward operational risk and more complex emerging risks like nanotechnology are some of the other challenges. With a wide range of exposures all affecting food safety and with the potential to lead to a product recall, risk managers should ensure that crisis management planning is an integral part of their risk management. As large market recalls appear to increase in frequency and companies’ brands become more exposed to consumer, media and regulatory scrutiny, it is critical that companies have the right systems in place to protect their brand and reputation in a serious product recall situation.

Insurance

Product contamination insurance is a specialty insurance and risk management product aimed at food and drink businesses. The market for this product has been growing in recent years due to an increased demand for coverage. Coverage is provided for recall expenses through to the policyholder’s loss of profit and rehabilitation costs. The insurance package is more than a risk transfer policy and includes a crisis and risk management service that offers policyholders both pre-incident risk consulting as well as crisis management support should a contamination issue arise.

Not all recall insurance operates the same way and risk managers should carefully assess the breadth of cover and consulting services made available to them. Some insurers will make available a percentage of the policy premium for pre-incident consulting which is free to the policyholder.

Product contamination insurers will typically make available specialist consultants who can help companies in managing their exposure.

Crisis and risk management

While many food companies have recall plans in place they often lack crisis management plans which potentially leaves them exposed to losses outside of their control in a recall situation. Being prepared for a crisis in advance of it happening is vital and can be the difference between disaster and recovery after a recall.

Companies with effective crisis management systems in place will regularly run simulations to test their traceability and recall systems as well as management’s ability to respond to a randomly selected scenario. In order to be able to respond effectively a company’s crisis management system should address everything from supplier management and quality assurance procedures to product security and media training.

When an incident occurs companies can call on these crisis consultants 24 hours a day. The consultants will not only provide extra support, but also have the latest expertise in the field.

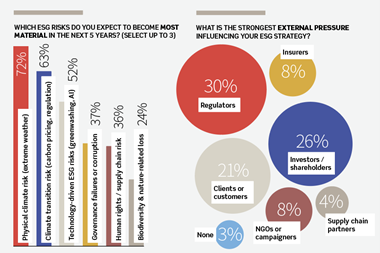

Insurers can help companies manage these emerging regulatory, supply chain and reputational risks by working with them to ensure that they have the highest standards in place with regard to food safety and product recall. This can involve reviewing regulatory compliance, quality assurance and supply chain risk, recall and crisis planning. In the current environment it is particularly important that companies ensure that they are both aware of their regulatory obligations and are compliant, as well as protecting their brand reputation.

Postscript

Ed Mitchell, global product recall manager, Edward.Mitchell@xlgroup.com and Thomas Zanner, deputy casualty underwriting manager continental Europe, Thomas.Zanner@xlgroup.com, both of XL Insurance

No comments yet