STMicroelectronic explains how its Resilience Site Index is changing the way the firm does business

“We like to position ERM (Enterprise Risk Management) as an enabler of our strategy,” said Franck Freymond, chief audit and enterprise executive at STMicroelectronic.

He was speaking at the Risk-!n conference in Zurich about the firm’s journey towards resilience – a project that has been underway for over five years now.

The firm’s core strategy is based on three key pillars:

- Smart mobility: Helping car manufacturers make driving greener, safer and more connected

- Power and energy: Enabling industries to increase energy efficiency and use of renewables

- Internet of Things: Supporting the proliferation of smart, connected, IoT devices.

However, this strategy needs to overcome a growing list of interconnected risks. Freymond pointed to people, geopolitics, climate change, supply chains, and digital and infrastructure as the pillars that are currently top of mind.

“We now live in a world characterised by a lot of uncertainty. This volatility is creating headwinds and tailwinds,” he told the audience.

”We try to maximise those opportunities as much as we can. On the risk side, we need to define the right mitigation strategy and cap the downside.

“Being resilient is not just a critical to success factor, but an operational imperative.”

The firm already had a good basis in resilience, for instance through ISO 22301 certification. However, they wanted to take things to the next level. To do this, they created a roadmap.

The idea was to make ERM more relevant from a strategic perspective and to understand where there was room for improvement through alignment and integration with company goals.

The first step was to develop company resilience objectives. For STMicroelectronics these are defined as:

- Ensuring the main sites remain operational (no significant interruptions or damage)

- Selectively developing back-up options across internal and external sites

- Ensuring continuity of the full supply chain, including third parties

- Managing the scrutiny from clients and other stakeholders

- Improving company-wide capability to respond to clients.

Behind those headings was a comprehensive roadmap with many more goals for improvement over many years.

Jean-Michel Paris, head of corporate risk at STMicroelectonic, said: “We’ve been working on ERM for many years, but it wasn’t always systemic. We operate a network of very large sites, almost like cities in their own right with thousands of people.”

“The tradition in this world is to work on a business continuity plan (BCP). And yes, you need to have these, but how do you identify the good ones? The BCP is not enough, you need to try and discover the structural weaknesses of every single site so you can work on them.”

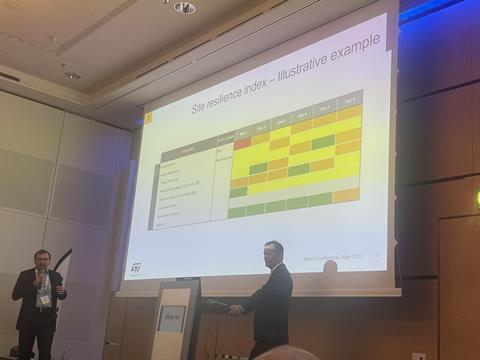

This need ultimately led to the creation of a systemic resilience capability, which STMicroelectronics calls the Site Resilience Index.

”The BCP is not enough, you need to try and discover the structural weaknesses of every single site so you can work on them.”

This index allows the firm to measure the resilience of every single one of its sites worldwide against a set of predetermined characteristics and goals. This has allowed ST Microelectronics to make significant changes to improve the business continuity of its manufacturing processes.

For instance, ST has highly specialised sites with a lot of expertise, but that means if production is halted due to external factors it cannot be instantly shifted to another location.

However, thanks to the index, the company is building flexibility so it is able to manufacture many products across several locations to mitigate that risk. Similarly, it is helping the company identify and eliminate regional concentration risk amongst suppliers.

”This reduces the risk of having to use the BCP and it gives us a seat at the CapEx discussion.”

Perhaps even more impressively, the index allows the risk team a seat at the table in CapEx discussions, as it provides a strategic insight into which sites need investment from a business continuity perspective.

Freymond concluded: “It leads to a totally different way of looking at resilience. You start looking at your site not just in terms of the BCP, which you need to have, but in terms of your resilience improvement plan.

“By looking at it in a systemic way you know where you need to channel your structural investments to improve resilience. This reduces the risk of having to use the BCP… and it gives us a seat at the CapEx discussion.”

“The timing was fortunate because it was one year before the global pandemic crisis, and the fact we’d already started to assemble building blocks with regard to crisis management and resilience helped us a lot in those difficult years.”

No comments yet