The growing complexity of global trade networks makes managing supply chain risks more critical than ever.

In association with Marsh

Over the past year, businesses have faced challenges from the war in Ukraine, global economic instability, political unrest in the Middle East, a landmark election year, and the effects of climate change.

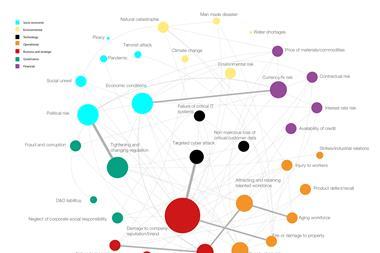

This has led many risk managers to re-evaluate supply chain strategies, seeking greater certainty in an unpredictable world. The landscape encompasses a variety of challenges, from structural and site-specific risks to geopolitical and climate concerns.

Structural risks often arise from single points of failure or concentration risks, where supply chains rely heavily on a few key suppliers. A notable example was the 2011 disruption in the automotive industry following the earthquake and tsunami in Japan.

James Crask, managing director, global head of multinational clients, advisory at Marsh, explains: “The supply chain for a lot of automotive manufacturing companies were based in Thailand at the time. And at that point, there was also significant flooding. This resulted in some significant losses for some Japanese automotive manufacturers.”

Geopolitical tensions and climate change also add to the complexity. For instance, the shift from China to countries like Vietnam and Malaysia, as part of “China plus one” strategies, mitigates some risks but introduces others.

Crask explains: “You’ve got concentration risk and you’re also potentially building longer tail climate risk where you’ve got all these sites in an area that might be at higher risk of heat stress or flooding in 30 years’ time. There is also the potential for quite seismic changes in the way the tariff regimes are going to work. This creates new supply chain risks that organisations need to manage, but also the opportunity to re-wire supply chains for resilience.”

Visibility is key

Visibility of direct suppliers (known as tier one) along with the indirect supply chain (tiers 2, 3 and beyond) is essential for effective supply chain risk management. However, many organisations lack comprehensive oversight beyond their immediate suppliers, partly due to reliance on manual data gathering which has until recently been the norm for most organisations. This approach is insufficient for today’s complex, multi-tiered networks.

Technological advances including AI large language models have significantly moved the needle on supply chain management. For instance, LLMs can now “read” billions of data records quickly, such as trade data and shipping manifests, to allow risk managers to better map supply chains, highlighting critical pinch points and emerging threats. This means that where traditional approaches tended to be limited to being more reactive to disruption risks, it is now possible to become more proactive.

Crask says: “The challenge is that most organisations tend to be looking out of the rear-view mirror rather than the windscreen when they’re conducting risk assessments on issues such as financial stability.

“The most critically important thing right now is visibility of key vulnerabilities. This is the start of the process of moving from a reactive posture to one of proactivity with proper risk management processes. Visibility starts with a really solid understanding of what your supply chain actually looks like.”

How to enhance supply chain risk management

Once organisations identify vulnerabilities, risk managers can employ strategies to mitigate them.

These strategies will vary by sector and risk exposure. The most obvious would be holding additional stock as a buffer against interruptions. While this can buy time by giving an organisation some cushion to a disruption, it can also be costly since working capital will need to be tied up in holding stock that may only be needed on a rainy day. Getting the balance between efficiency and resilience is key.

More innovative approaches include vertical integration, where organisations acquire critical parts of their supply chain, a method often seen in sectors like defence or critical infrastructure. This can help to safeguard against single points of failure. Some organisations also offer financial or expert support to critical suppliers to ensure their operations continue during crises.

Influencing risk management and resilience activities of second- and third-tier suppliers is more complex but possible. Leveraging relationships with direct suppliers can drive changes further down the chain, while diversifying tier-one suppliers can also help mitigate risks, particularly by selecting those with different supplier bases.

The benefits of getting supply chain right

Effective supply chain risk management delivers tangible financial advantages. A recent Oliver Wyman study found that companies prioritising supply chain resilience see revenue increases and competitive advantages.

Crask said: “Clients that put emphasis on managing supply chain risk, generally speaking, see an 8% increase in revenue relative to peers, and a 19% increase in profit, which suggests they’re better at managing some of the cost increases.”

Another key benefit is reputational. Organisations that demonstrate resilience are likely to be viewed as trusted providers, fostering customer loyalty and driving higher sales.

Ultimately, as the global risk landscape evolves, organisations must adapt. By leveraging technology and adopting resilient practices, businesses can safeguard operations, withstand disruptions, and thrive in the face of uncertainty.

No comments yet